Fewer

bad parts.

The powerful clutch and brake mechanism delivers good parts from the first to last stroke. The mass balancing and dynamic damping system ensure that no vibrations are transmitted into the stamping process.

The powerful clutch and brake mechanism delivers good parts from the first to last stroke. The mass balancing and dynamic damping system ensure that no vibrations are transmitted into the stamping process.

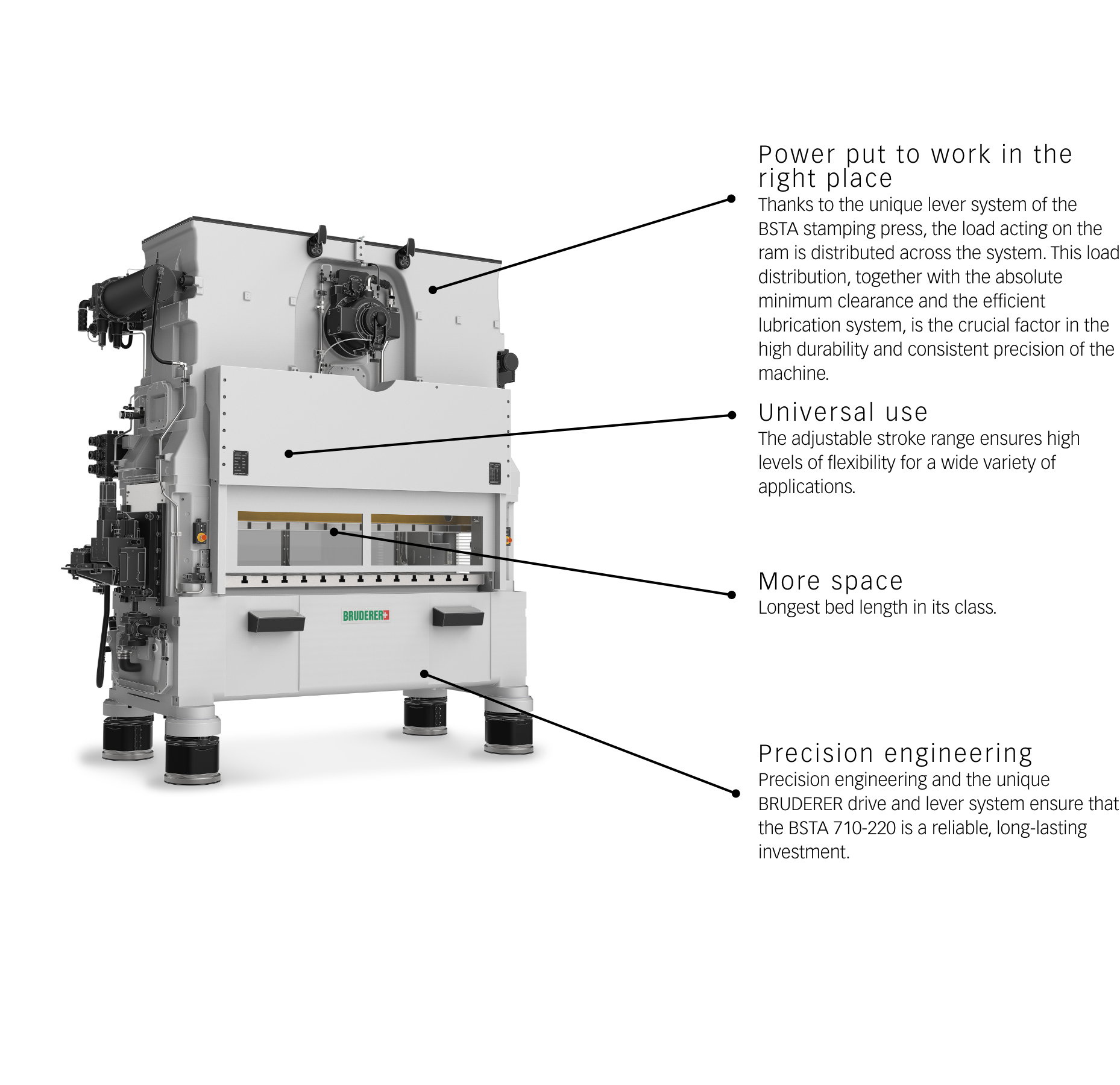

Thanks to the unique lever system of the BSTA stamping press, the load acting on the ram is distributed across the system. This load distribution, together with the absolute minimum clearance and the efficient lubrication system, is the crucial factor in the high durability and consistent precision of the machine.

710-220

2200 mm

Min. 100,

Max. 850 spm

710 kN